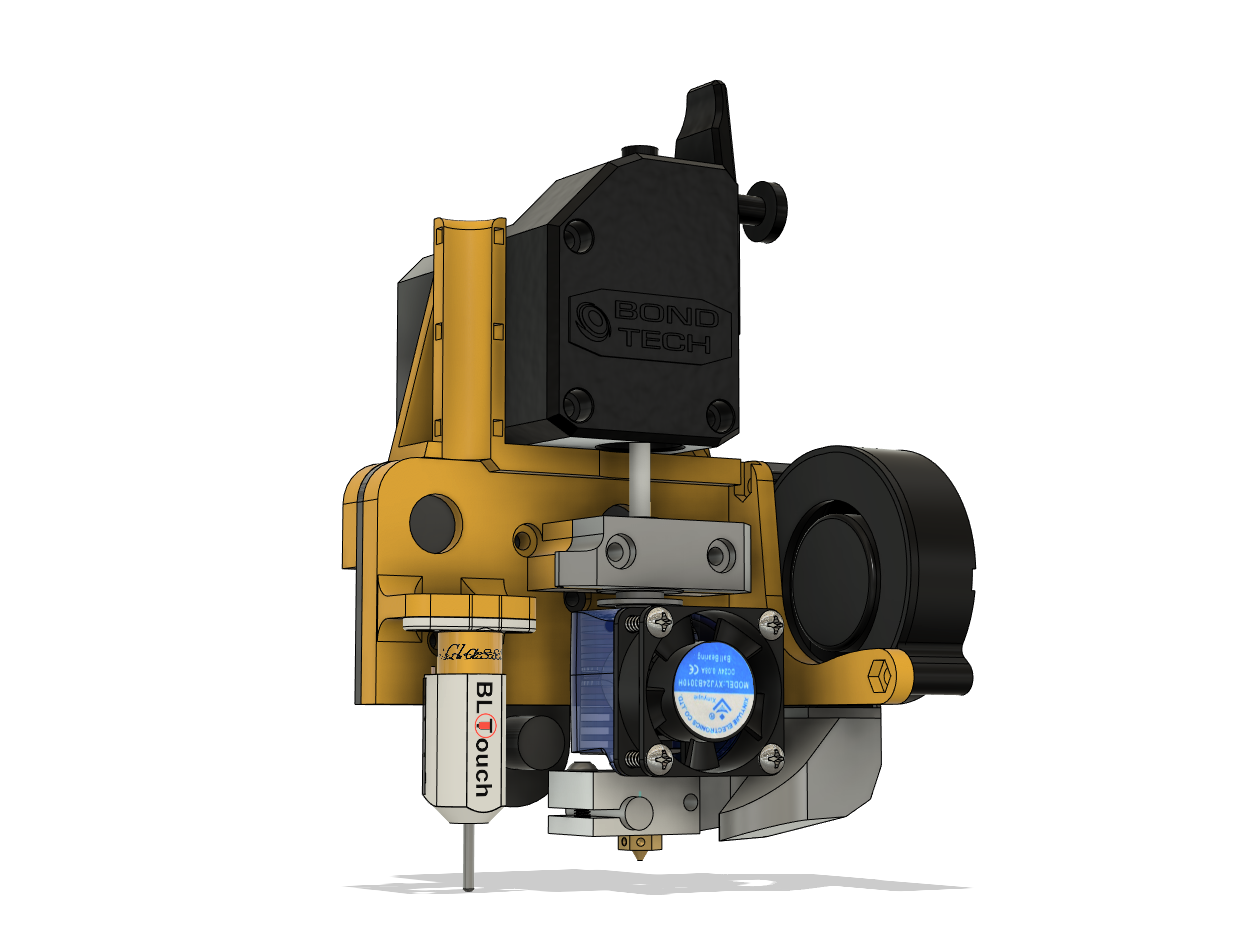

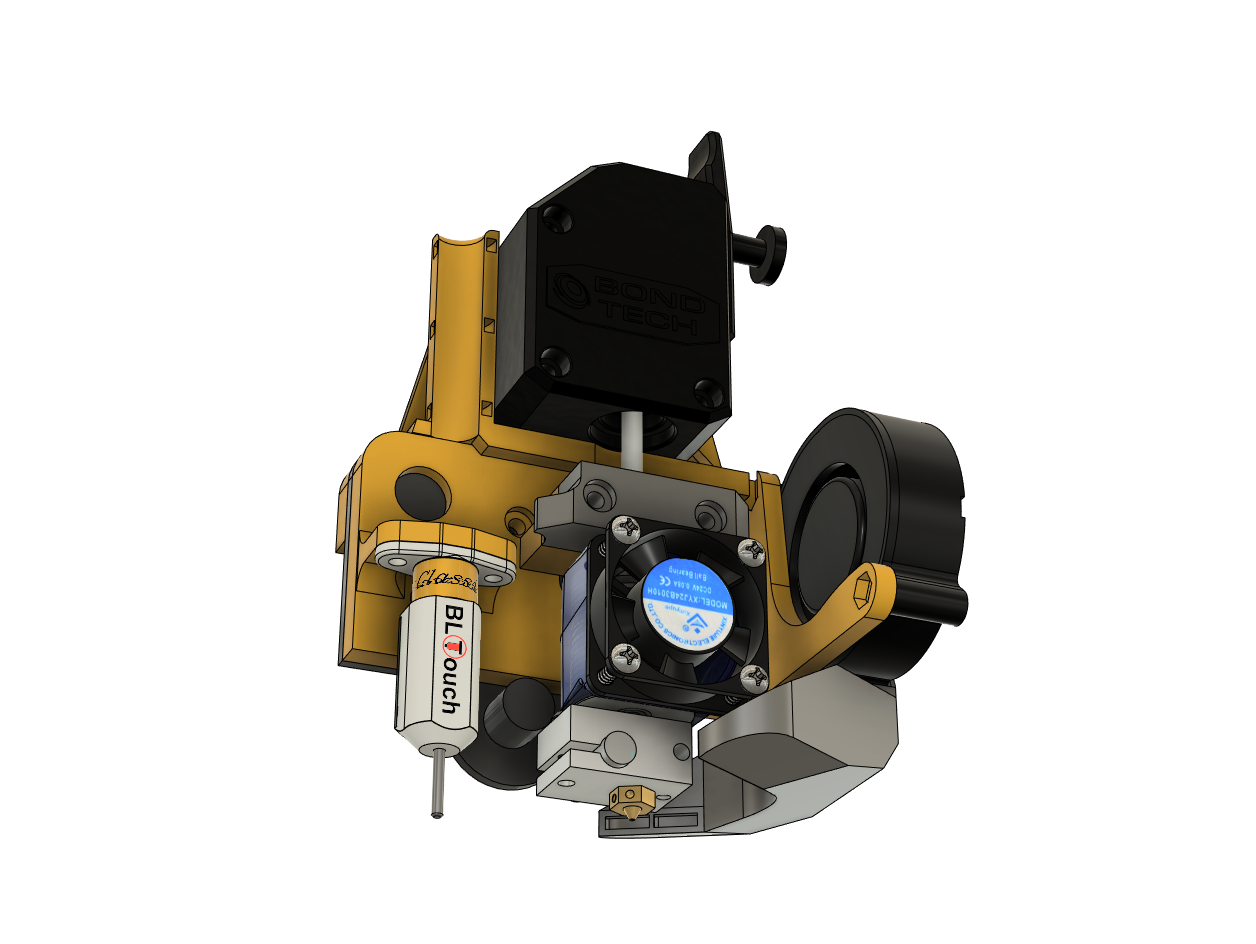

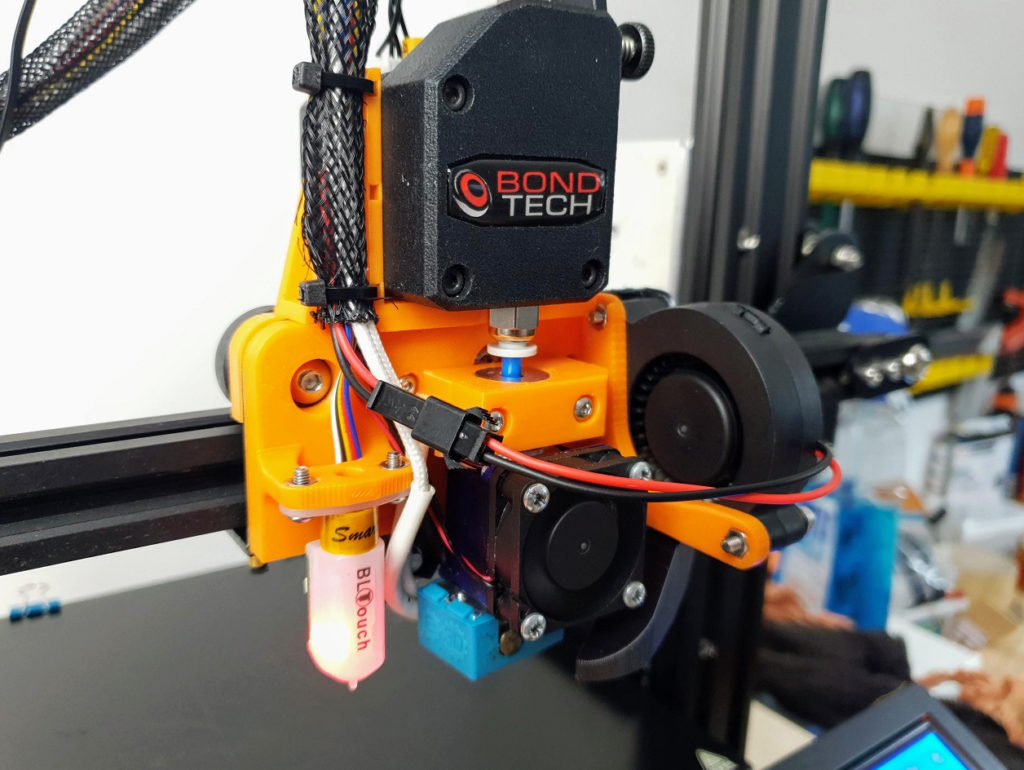

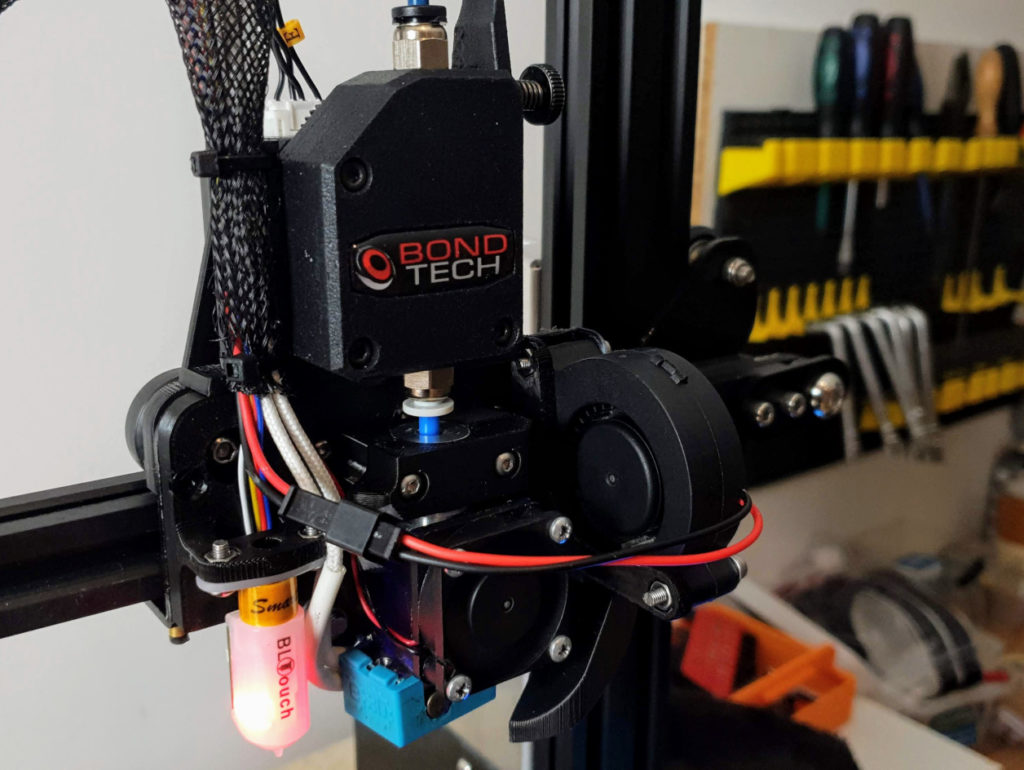

This is the “SpeedDrive Edition” of my BMG E3D V6 Direct Drive for Creality Ender 3 & CR-10, inspired by the excellent SpeedDrive v1 from sashalex007

The main change is the motor location: As in the SpeedDrive V1 from sashalex007, the motor is now mounted behind the carriage. This provides 2 benefits:

- the weight of the extruder motor (~220 grams) is now supported by the X rail

- the center of mass is much closer from the hotend (The original BMG E3D V6 Direct Drive was a bit front heavy due to the motor location)

The better mass distribution of the carriage should allow higher accelerations with less ringing.

This design comes with some new trade-offs though:

- The hotend is no longer directly connected to the extruder output => the PTFE tube is longer (66 mm instead of 37 mm)

- More 3D printed parts / parts are more complex + supports from the build plate are required.

Design requirements

The high level requirements for this design were the following:

Hotend directly connected to the extruder, shortest distance between the extruder & the hotend (PTFE tube length = 37 mm only!): NOT MET: The motor is now mounted behind the carriage => The hotend cannot be directly connected to the extruder output => the PTFE tube is longer (66 mm instead of 37 mm)- The motor’s centre of mass should be as close as possible to the middle of the X extrusion for absorption of its significant linear inertia at speed. (SpeedDrive Requirement)

- Orientation of the motor shaft perpendicular to the X axis for good absorption of rotational inertia (SpeedDrive Requirement)

- Minimalist, compact & lightweight

- Non adjustable to reach the highest accuracy/repeatability

- Optimized & highly efficient cooling

- Compatibility with all filaments types (flexible filaments, TPU, PLA, ABS)

- Cable management

- Good visibility on the nozzle

- No reduction in print volume (220x220x250 mm)

Easy to print (support free): NOT MET: Supports from the build plate are required- Easy to install & maintain

What you need

| 3D PRINTED PARTS | |

| Download the .STL files for the BMG E3D V6 “SpeedDrive” |  |

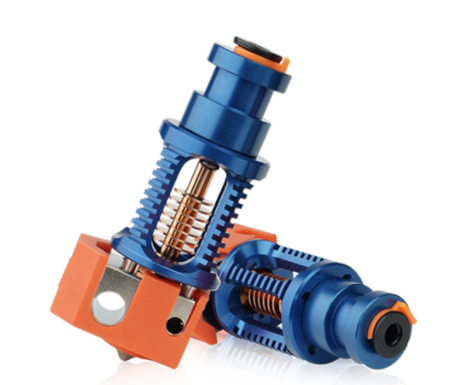

| EXTRUDER | |

| BondTech BMG extruder (Standard Version) + Bowden adapter |  |

| HOTEND | |

| E3D V6 hotend (24V Direct Drive) or E3D REVO 6 (24V) or Phaetus Dragon ST or HF |    |

| AUTO BED LEVELING SENSOR | |

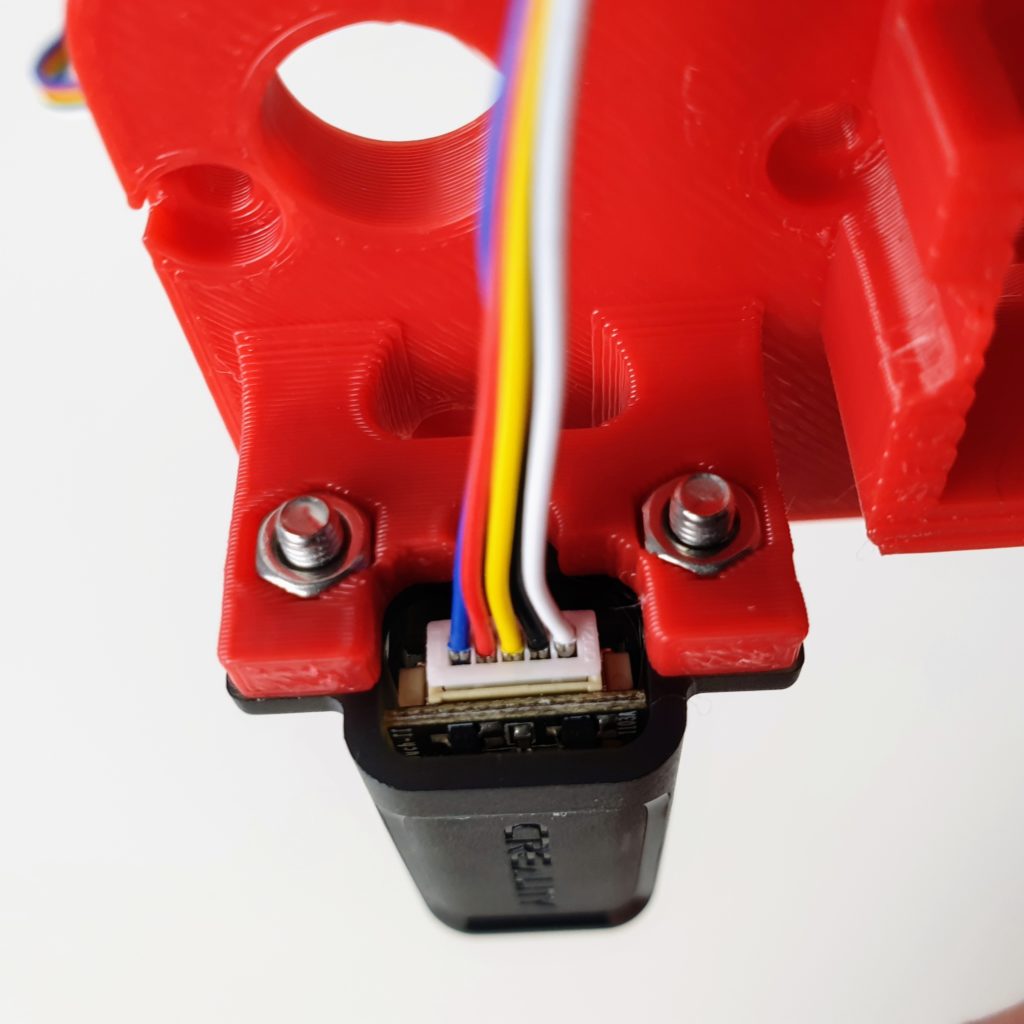

| Antclabs BLTouch or Creality CR Touch |   |

| HARDWARE | |

M3 Hex Socket Head Cap Screws Bolts Nuts Washers Assortment Kit M3x20mm bolts (x2) M3x16mm bolts (x2) M3x12mm bolts (x1) M3x8mm bolts (x4) M3 nuts (x5) |  |

| STEPPER MOTOR | |

| 23.5mm height maximum Usongshine Nema 17 Stepper Motor (17HS4023) |  |

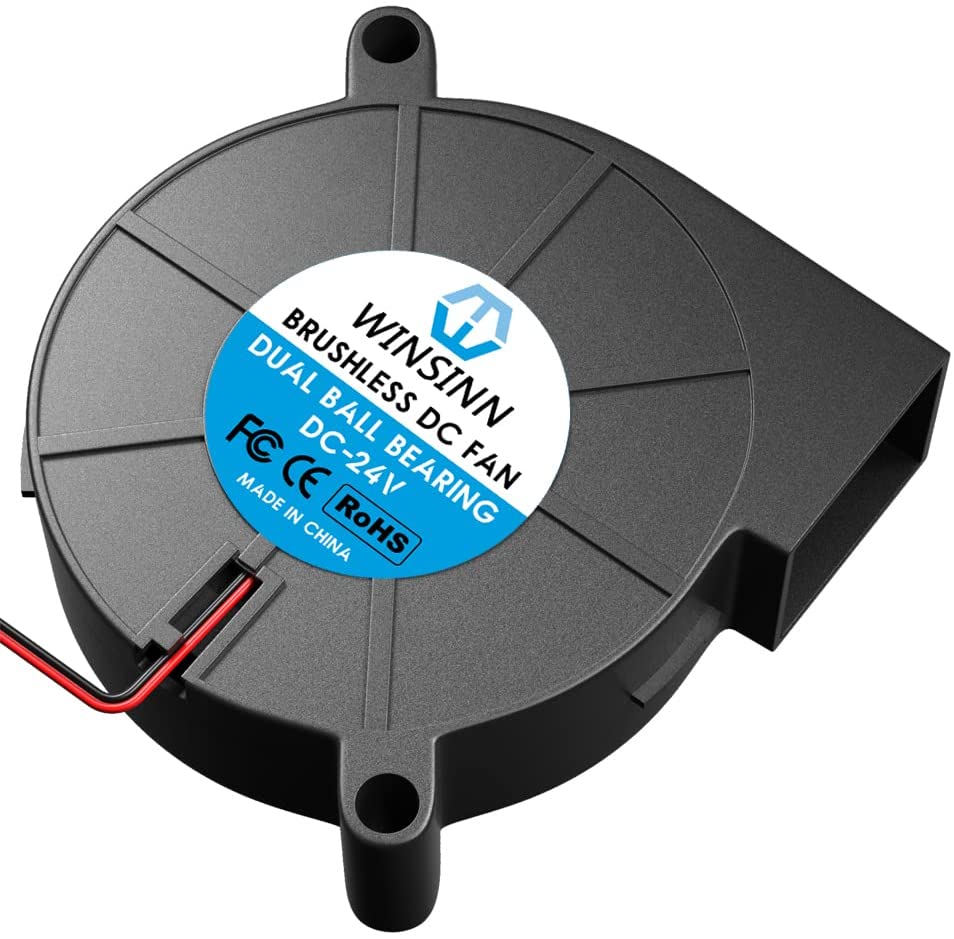

| PART FAN | |

| 5015 Blower Fan (24V) |  |

| PART FAN CONNECTOR (optional) | |

| JST Plug Connector 2 Pins Male Female |  |

| ZIP TIES (x3) | |

| Zip Ties 2.5 mm/0.07 inch wide |  |

| STEPPER MOTOR EXTENSION CABLE (recommended) | |

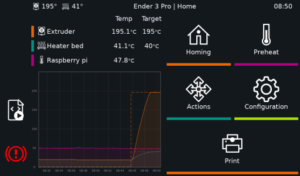

Firmware

Download the Marlin firmware for this configuration on GitHub

Download the Klipper firmware for this configuration on GitHub

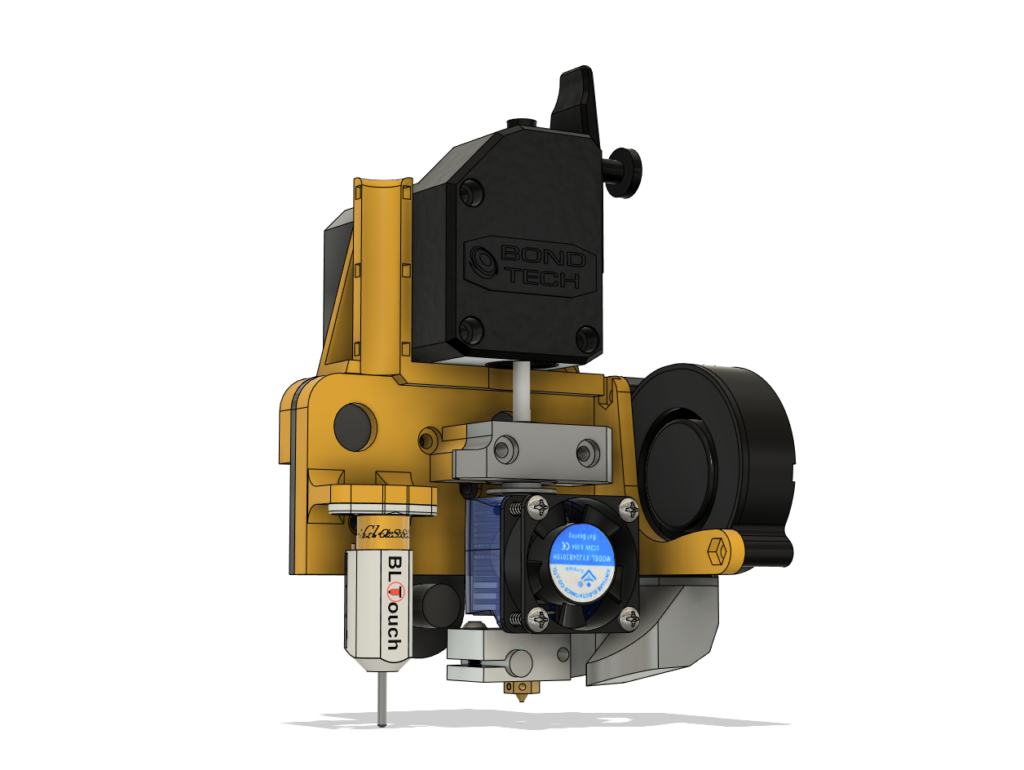

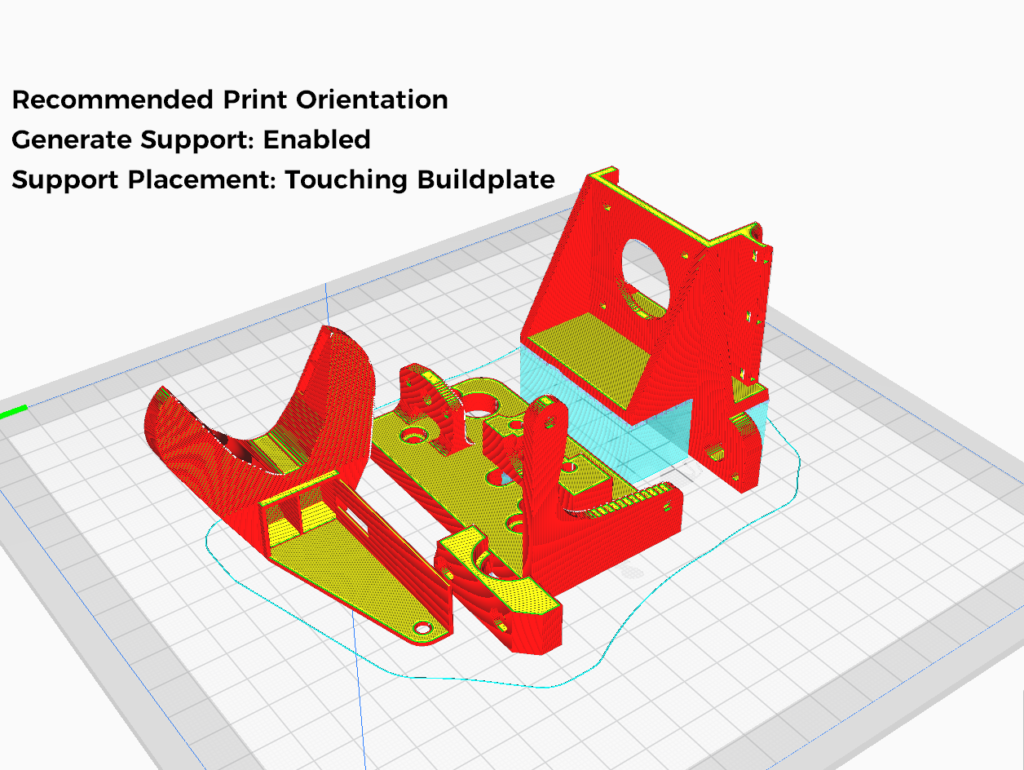

Print settings

I printed these parts in Sunlu PLA+. My print settings (Ultimaker Cura):

- Layer Height: 0.25 mm

- Line Width: 0.4 mm

- Wall Thickness: 0.8 mm (=2 walls)

- Top/Bottom Thickness: 0.75 mm (=3 layers)

- Infill Density: 20%

- Printing Temperature: 230 deg C

- Build Plate Temperature: 70 deg C

- Enable Print Cooling: Enabled

- Fan Speed: 100%

- Initial Fan Speed: 0%

- Regular Fan Speed at Layer: 2

- Generate Support: Enabled

- Support Placement: Touching Buildplate

The parts are oriented like shown on the image below:

Makes

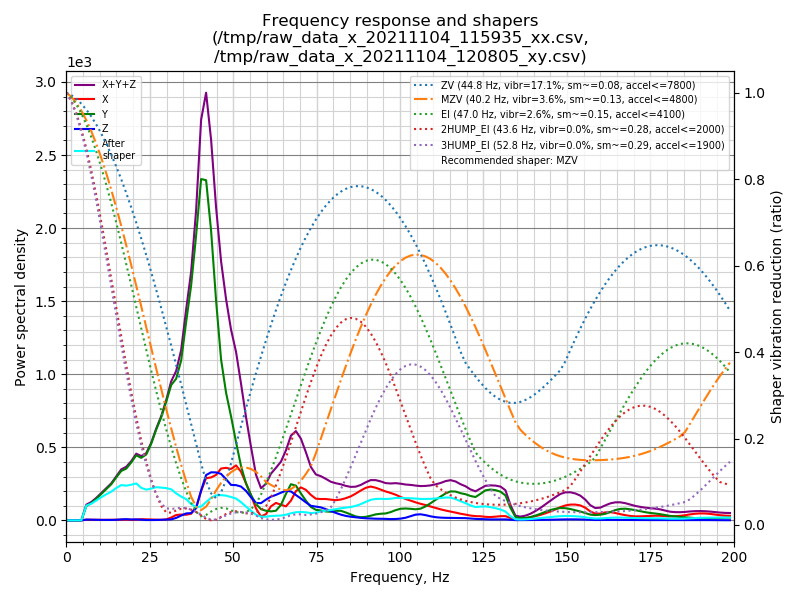

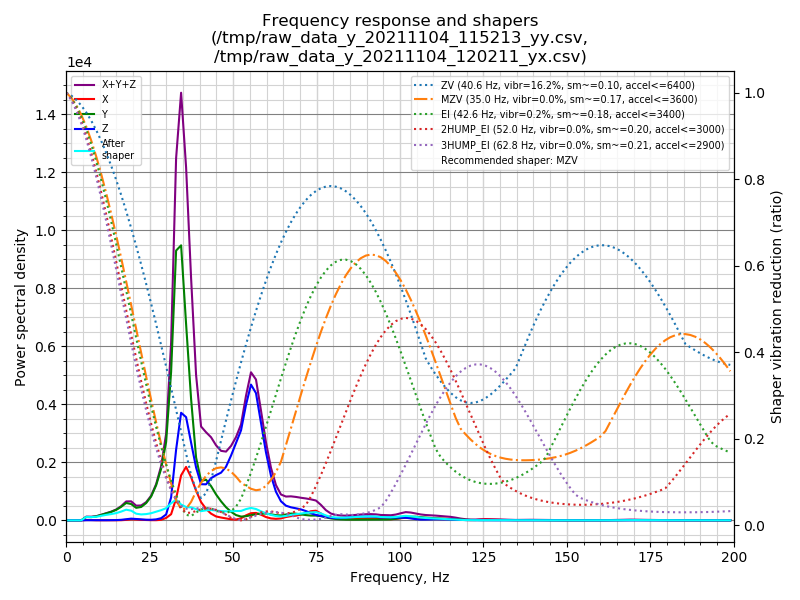

Measured resonances (Klipper)

Below are the measured resonances of my setup. These are provided for information only as they vary from printer to printer and must therefore be measured for each printer.

From a resonance point of view, the SpeedDrive version is an improvement over the original version. The original version had 2 resonance frequencies: one at 32 Hz and one around 85 Hz. The SpeedDrive version has only one main resonance frequency at 45 Hz. This allows to use the MZV shaper instead of 3HUMP_EI, resulting in less smoothing of parts and higher possible accelerations…

Unfortunately, the max acceleration possible with the Ender 3 is still limited by the Y axis due to the bed slinger design.

Change log

- 20220207: v48 -> v49: Update the Auto Bed Leveling bracket to be compatible with both the BLTouch and CR Touch

- 20211203 (v48) Shifted everything (hotend, motor, BMG, blower) forward by 2 mm to increase clearance between the motor and the frame + increase clearance between pom wheel and motor plate based on feedback from user Ultrazauberer

- 20211107 (v46) Add mounting holes for Ender 3 V2 + Fix small misalignment between extruder output and hotend

- 20211103 (v44) Fix the middle hole on the back of of the motor plate (was too small)

- 20211103 (v43) Initial release